The Power of JDF in RISO Cut-sheet Print Workflows

In the printing industry, automation has evolved from buzzword to crucial necessity for tackling challenges like rising costs, the shrinking skilled labor pool, and bringing more efficiency to print workflows. To achieve true automation requires a streamlined approach that eliminates unnecessary touchpoints, reduces costs, and minimizes errors. Leveraging industry best practices, Solimar supports RISO production cut-sheet print solutions using Job Definition Format (JDF) and Job Messaging Format (JMF) to provide an infrastructure for efficiency through automation!

While we often think of automation as physical, more related to machines, software automation is the powerful, essential element of process automation. JDF and JMF emerged as the enabling processes to bring data capture and task enablement to job tracking and process integration.

The power of JDF is that the file can contain the definitions for every process required for a print job across every type of printing method using the language of an eXtensible Markup Language (XML) schema. Think of JDF as the set of instructions, and JMF as the connecting framework between the JDF instruction set and other software solutions and equipment.

Job Definition Format (JDF) is an open standard, XML-based file format that simplifies information exchange between different applications and devices enabling automation of print and mail production processes.

Job Messaging Format (JMF) is the return handshake of device status information.

The JDF Electronic Job Ticket defines the entire print production process from order-entry to final delivery.

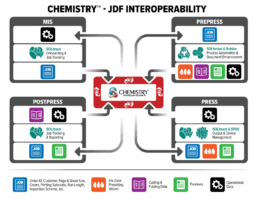

Solimar uses JDF/JMF as one communication method to acquire data that updates workflow processes and applications as needed. The Solimar® Chemistry™ platform products Rubika®, Solimar® Print Director™ Enterprise (SPDE), and SOLitrack™ leverage JDF to automate communication and supply data to tracking elements.

Solimar Solves the Three Top Challenges in Digital Printing with JDF

JDF-driven data exchange is now commonplace in digital printing. Both web-fed and cut-sheet digital print production are well-suited to JDF for page-level finishing, bi-directional communication, and consumables tracking.

1. Getting the Right Finishing

Page-level finishing includes instructions to automate media settings, tray pull locations, and in-line finishing operations like stapling and folding. The instructions are interpreted by the digital front end (DFE) based on the capabilities of the digital printer. Page-level finishing allows the printer to execute the instructions for each job, bypassing the labor of an operator assigning them through the DFE. Unlike proprietary job tickets, PostScript® SetPageDevice commands, or Document Part Metadata (DPM) in a PDF file, JDF is not proprietary and is more widely adopted across print industry vendors. Whether you are working with PDF, PCL, AFP, or PostScript, Solimar solutions can convert the embedded finishing commands to JDF before sending them to any compatible printer DFE.

2. Controlling Process Communication

JDF/JMF improves bi-directional communication between printers and software systems beyond the capabilities of older protocols like IPP or SNMP. Two-way communication ensures that a job’s status is known. Did the job fail? What percentage of the job is printed? Did the job complete? Were there any errors? These status updates supply transparency to operators and managers so the work can be effectively and efficiently produced. The updates also enable automation through other integrated software solutions like a print MIS. For example, a job completion status could automatically trigger a notification to the client in addition to automatic invoicing.

3. Understanding Consumables

In a mixed-vendor, JDF-enabled printing environment, JDF is a universal format to capture this information from different printing equipment and DFEs. As the print job is being printed, the DFE can send the available machine data for time and quantities, along with ink and paper usage, using JMF messaging that updates the job’s JDF data. On job completion, Solimar solutions can retrieve, store, and report valuable data for ink and media usage for tracking consumable usage across all production devices.

Process Automation with JDF in Action

JDF can form the foundational infrastructure for complex workflow automation. Many vendors provide easily accessible web hooks, APIs, or other mechanisms to share data using JDF/JMF to create a reliable data exchange network. RISO and Solimar work together to make it easy, as the team at a leading North America Insurance Company learned during their implementation of the Chemistry Platform Suite, including the live visibility and job tracking dashboard — SOLitrack, along with three RISO Comcolor GL7430s, 2 in Massachusetts and 1 in Connecticut.

RISO and Solimar worked with the customer to define and streamline their workflow by passing their incoming AFP and PDF files to Solimar Print Director Enterprise (SPDE) for normalization of all inbound files to optimized PDF. When that process is complete, SOLitrack is updated so the team has visibility, and the files move to the next steps in process automation managed by SOLfusion and the Solimar Indexing Tools. This is where indexing and re-engineering are managed, and once again the job status is updated in SOLitrack. Document re-engineering is performed by Rubika, stripping annotations, adding banner paged and finishing commands, generating job tickets, splitting, and concatenating as the rules require. A practical benefit is that job tickets, inserter control files (ICF) and MRDF files are generated at this step and SOLitrack is again updated.

As the files are queued for print, SOLitrack watches and continues to update the status of each output device and the files assigned to them. In the cut-sheet workflow managed by Solimar for the RISO Comcolor devices, the customer has real-time visibility to every part of their document production workflow.

Solimar JDF Job Ticketing brings powerful automation to production print workflow. Whether it is page-level finishing, improved bi-directional communication, or tracking of consumables used, JDF and JMF keep the staff informed. These three automation wins can make a significant impact in supporting customers and their applications as exemplified by the leading North America Insurance Company. Let Solimar show you how to win with JDF in your print workflow!

Ready to discuss your needs and questions? Let’s have a chat!Ping us at SOLichat@solimarsystems.com

For more information, call the Solimar Sales Team at +1.619.849.2800.